|

|

Home ::

Troubleshooting Your CO2 System

Troubleshooting Your CO2 System

| Keg not tapped properly: |

Have a look at the tap on the keg and make sure you have it in the open position. Depending on the style of tap you have, this is achieved by twisting the "T" handle clockwise, or pulling out on the handle and pushing it down. (red instructions)

|

| Tank or regulator not set properly: |

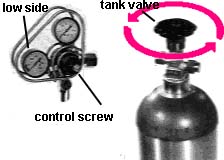

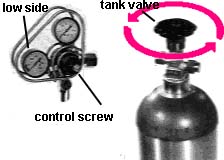

Turn the tank valve on the to of your CO2 tank on. (counterclockwise, red instructions).

If your low side gauge has no reading try turning the control screw clockwise (after being sure the tank valve is open).

|

| Tank out of CO2: |

If you do not have a high side gauge, you can tell by removing the regulator. and turning on the tank valve for a second or two. If the gas escapes and doesn't stop until closed, your tank has CO2. If no gas escapes or you get a short burst and nothing, you are out. |

| Frozen or broken regulator: |

You can check this by removing the tap from your keg and leaving it in the open position (after checking to see if you have CO2 in your tank). Turn the control screw and see if you can increase the volume of gas escaping from the tap. If you cannot change that flow you will most likely need a new regulator or a rebuild job. |

| Line and faucet problems: |

First check for blockages in the faucet assembly, then the line. Next, make sure that that the lines are connected properly. Your gas should (in most cases) come into the side of the tap and the beer exits through the top.

|

| Warm and/or agitated beer |

When your beer is warm the gas dissolved in it finds it easier to come out of solution causing it to be very foamy. Agitating a keg can have the same results, but it settles down relatively quickly when cold. A warm agitated keg can take several hours to calm down. |

| Over carbonated beer: |

This happens when the keg has been left cold and under too high a pressure for too many hours. The beer incorporates the additional gas and then it expands out when it is in a lower pressure environment (your glass). Avoid putting additional pressure on your keg for any reason. If you have already over carbonated beer, relieve the pressure by turning off your tank valve and opening the release valve. The low side gauge will drop down to zero. Let the keg rest for 30 or 40 minuets with the tank valve off. The low side gauge will build pressure again, relieve it again. Turn on your tank and check your beer flow. Repeat this process until you beer flows properly. This can take several attempts to solve.

If you cannot get your beer to settle you may need to adjust your low side pressure. |

| Low side pressure too high: |

Turn the tank valve on the to of your CO2 tank off (clockwise).

Turn the control screw on your regulator counterclockwise one full turn.

Pull the release ring until all the pressure is released. Your low side gauge should drop to 0 psi.

Turn the tank valve on the to of your CO2 tank on (counterclockwise).

Your low side gauge should still read 0 psi. If not, repeat the previous four steps, turning the control screw on your regulator counterclockwise another full turn.

Slowly turn the control screw control screw clockwise until the low side gauge reads 2 to 3 psi.

Increase the flow by using the control screw until beer is flowing properly. The low side pressure is normally not any higher than 7 psi, so you want to do this a pound or so at a time.

|

| Frozen or broken regulator: |

You can check this by removing the tap from your keg and leaving it in the open position. Turn the control screw and see if you can decrease the volume of gas escaping from the tap. If you cannot change that flow, you will most likely need a new regulator or a rebuild job. |

| Beer leaks: |

Usually easily spotted. Often a loose connection or your tap or your faucet assembly may need cleaning. The washers and o-rings could use some lubing or replacing as well.

Occasionally it is the result of an old brittle or severed hose. Or one that is to large for it's barb.

Just replace damaged hose or incorrect connectors. |

| CO2 leaks: |

Usually a noticeable loss of CO2 in a short period of time is the indicator here.

Turn the tank valve on the to of your CO2 tank on. Open all valves including the tap. Spray the entire system with a soapy water solution from a spray bottle, concentrating on the connections. A leak will show up with bubbles in the soapy water. Check for worn or missing washers and o-rings and replace them. Tighten fitting and check for further leaks.

Occasionally it is the result of an old brittle or severed hose. Or one that is to large for it's barb.

Just replace damaged hose or incorrect connectors. |

|